Complete Guide to Safety Management and Quality Control for Ringlock Scaffolding Systems

Safety Management System

1. Erection and Dismantling Regulations

The most dangerous phases of scaffolding work are during erection and dismantling. Statistics show that nearly half of all fatal accidents in the construction industry are related to falls from height.

-

“Scaffolders’ Safe Zone” Concept: The UK NASC’s SG4:22 standard introduces the “Scaffolders’ Safe Zone” concept, requiring the creation of a safe collective protection area for workers by installing complete working platforms and guardrails at least 950mm high.

-

Principle of Avoiding Aerial Work: Prioritize pre-assembling large components on the ground before hoisting them into place as a unit, thereby reducing time spent working at height.

-

Importance of Ties and Anchorages: Research indicates that most scaffold collapses are related to insufficient or prematurely removed tie-ins or anchorages. These components must withstand at least 6 kN of force for 15 seconds without failure.

2. Personnel Training and Qualifications

-

Certified Operation: All scaffolding operatives should receive professional training and hold relevant certifications, such as the UK’s CISRS scheme.

-

Human Error Prevention: Studies indicate that human errors are most likely during scaffold dismantling and supervisory inspection. Companies should enhance training and education focusing on these areas.

-

Continuous Supervision: Trainees and new workers must operate under the supervision of qualified personnel. Regular safety briefings and toolbox talks should be conducted.

3. Risk Assessment and Planning

-

Preliminary Risk Assessment: A comprehensive risk assessment must be conducted before erection, identifying specific risks like fragile surfaces and adverse weather conditions.

-

Technologically Assisted Design: Using BIM and 3D modeling technologies to pre-plan scaffold erection is recommended to identify and resolve potential risks.

-

Fall Prevention Plan: Develop a detailed fall prevention plan that clearly establishes the principle of collective protection first, supplemented by personal protective equipment.

Quality Control Standards

1. International Standards and Testing Requirements

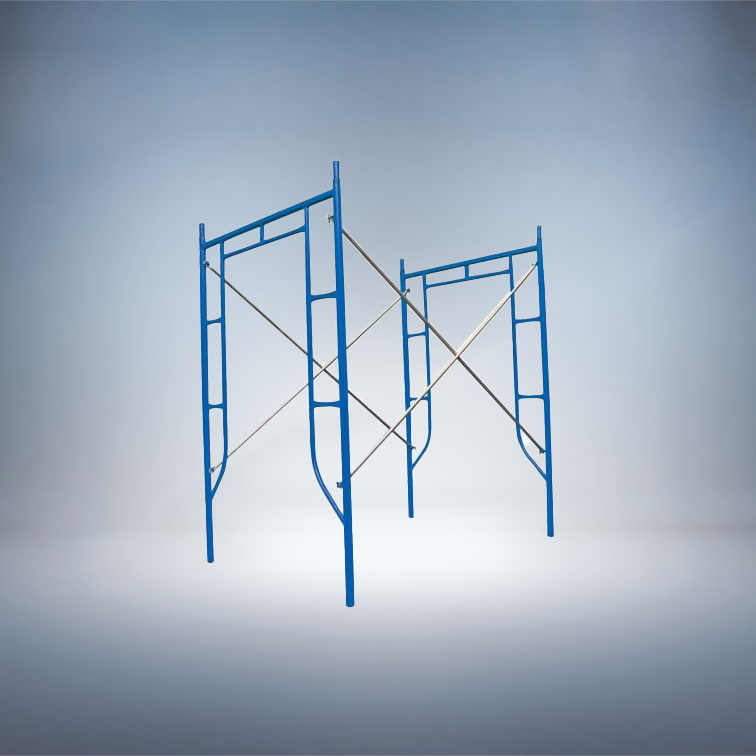

Ringlock scaffolding must comply with various international standards to ensure structural integrity and safety:

| Test Type | Applicable Standards | Test Content |

|---|---|---|

| Complete Scaffold Testing | EN 12811-1, EN 1004, AS/NZS 1576.3 | Overall load-bearing capacity, stiffness testing, prefabricated platform testing |

| Scaffold Accessory Testing | EN 74-1, BS 1139 | Slip resistance, anti-damage capability, deformation testing |

| Steel Tube Material Testing | EN 39 | Chemical composition analysis, mechanical performance testing |

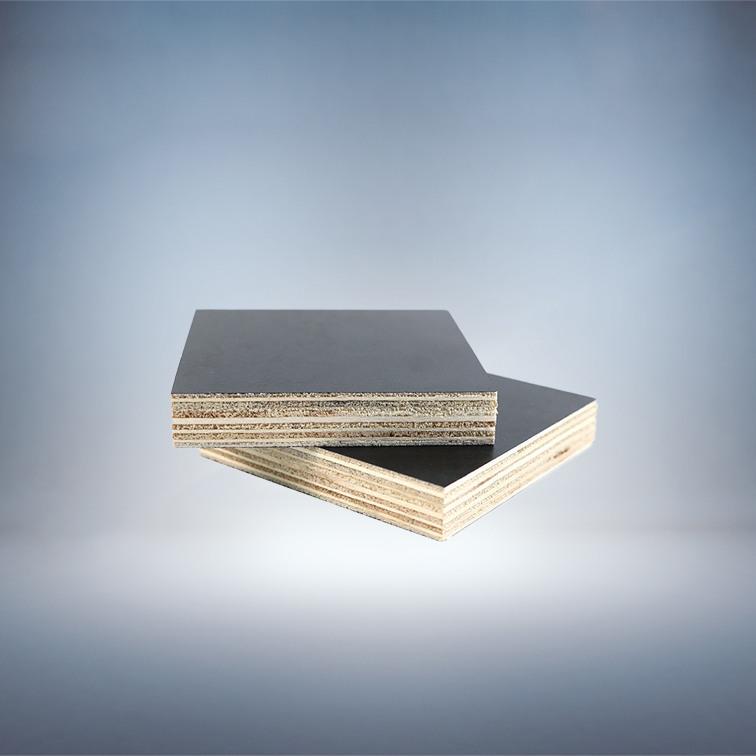

| Plank Testing | OSHA, EN 1004, AS/NZS 1577 | Stiffness testing, strength testing, uniformly distributed and concentrated load testing |

The Chinese Ringlock aluminum scaffold standard (T/CFSA 07—2021) also clearly defines its terminology, classification, technical requirements, and test methods.

2. On-Site Quality Control Measures

-

Daily Inspections: All personal protective equipment must be inspected daily and maintained regularly.

-

Anchorage Point Verification: Tie-in anchorages must be tested to ensure they can withstand 6 kN of force for 15 seconds without deformation.

-

Material Quality Control: Strictly control the quality of components such as steel tubes, couplers, base jacks, and castors to ensure they meet design specifications.

3. Document Management and Record Keeping

-

Inspection Records: After completion, a scaffold inspection report must be issued, such as Hong Kong’s “Construction Site (Safety) Regulations” Form 5.

-

Training Records: Training qualifications and records for all operatives should be properly maintained.

-

Design Documentation: Scaffold structure design plans and risk assessment documents need to be retained for at least three years.