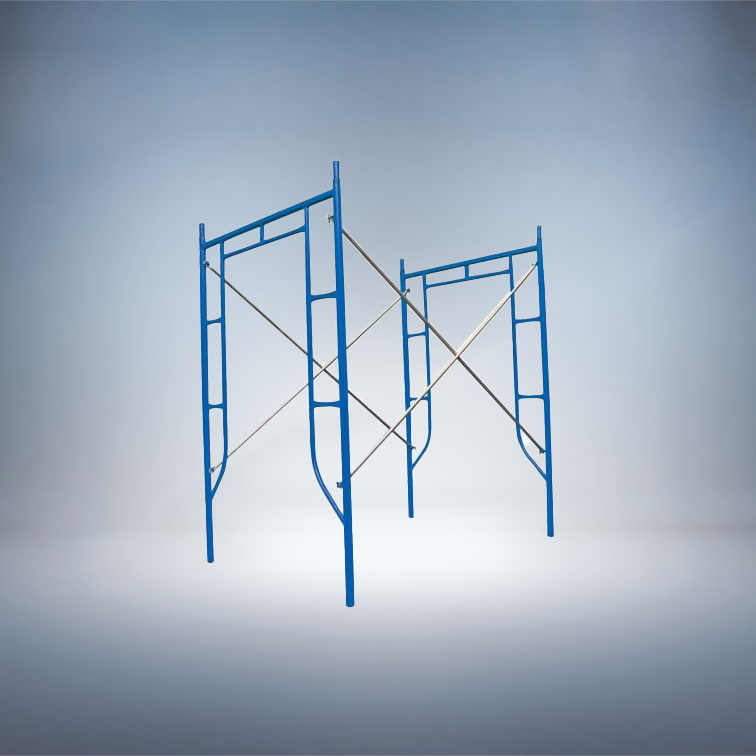

Why Is Ringlock Scaffolding the Safest Choice for Your High-Altitude Work? Unveiling Its Superior Safety Performance

In construction, bridge work, and various industrial maintenance projects, scaffolding safety is a critical factor that determines project success and, most importantly, the well-being of workers. Among various types of scaffolding, Cuplock Scaffolding (also known as Modular System Scaffolding) stands out for its unparalleled safety performance, making it the preferred choice for high-standard projects worldwide. This article delves into the five key safety advantages of Cuplock Scaffolding.

1. Superior Load-Bearing Capacity and Structural Stability

The core component of Cuplock Scaffolding is a rosette-like connecting cup with 8 slots welded to the vertical standard. This design allows for multi-directional rigid connections, significantly enhancing the load-bearing capacity of the standards—often several times greater than traditional tube-and-coupler scaffolds. Its structure boasts excellent integrity, functioning like a sturdy “steel module” that effectively resists swaying and deformation, providing an extremely stable and reliable working platform for workers and materials.

2. Unique Self-Locking Connection, Eliminating Human Error

Traditional scaffolding relies on the tightness of bolts, which can be prone to human error (e.g., insufficient tightening), creating potential hazards. Cuplock Scaffolding utilizes an advanced drop-forged blade and wedge system. When connecting the ledgers (horizontals), the blade is inserted into the cup and locked securely by a driving pin or wedge. This connection is robust, visually verifiable, and resistant to loosening, greatly reducing the risk of collapse due to insecure joints.

3. Modular Design for Simple, Standardized Installation

Cuplock Scaffolding features a unified modular design with fewer components and straightforward assembly steps. After basic training, workers can erect the structure quickly and accurately, much like “building with LEGO bricks.” This standardized process minimizes safety risks associated with installation errors, part mismatches, or arbitrary erection, ensuring every setup complies with safety regulations.

4. Excellent Compatibility with Comprehensive Safety Accessories

The Cuplock Scaffolding system is supported by a complete range of safety accessories. Whether it’s steel stairways for access, full-height guardrails, toe boards, or debris nets, they can be easily and securely attached to the framework. This creates a safer and more convenient working environment, effectively preventing falls from height and falling object strikes.

5. Outstanding Durability and Material Quality

The main components of Cuplock Scaffolding are typically made from high-strength, low-alloy steel and undergo hot-dip galvanization for corrosion protection. This makes them not only strong but also highly resistant to rust, ensuring a long service life. Even under harsh weather and environmental conditions, they maintain their structural integrity and safety over time, avoiding strength degradation caused by corrosion.

Conclusion

Choosing Cuplock Scaffolding is not just selecting a tool; it is committing to a higher standard of safety. Its exceptional load-bearing capacity, revolutionary self-locking mechanism, standardized installation, and long-term durability collectively build a solid line of defense. For project managers striving for zero-incident goals, Cuplock Scaffolding is the ultimate choice for achieving both efficiency and paramount safety.