Ringlock System

The Ringlock System is an advanced modular support system based on nodal connection technology. The system uses vertical standards with rosette plates as the load-bearing core, enabling instant rigid connections via the wedge-shaped ends of ledgers and diagonals, eliminating the need for loose bolts and fittings required by traditional scaffolding. Renowned for its exceptional structural stability, remarkable erection speed, and unparalleled safety, it is the preferred solution for modern large-scale projects seeking to replace conventional methods.

System Core Value:

Ultimate Safety: Rigid nodal connections and a stable structure offer load-bearing capacity far exceeding traditional scaffolding, ensuring the highest level of safety.

Maximum Efficiency: Loose-part-free, quick-connect design increases erection and dismantling speed multiple times, significantly reducing project timelines and labor costs.

Cost-Effective & Durable: All-steel construction with hot-dip galvanization ensures excellent durability, high reusability, and lower long-term cost of ownership.

Unmatched Versatility: Standardized modular design allows for flexible configurations to meet the demands of complex structures and various site conditions.

Description

1. System Overview

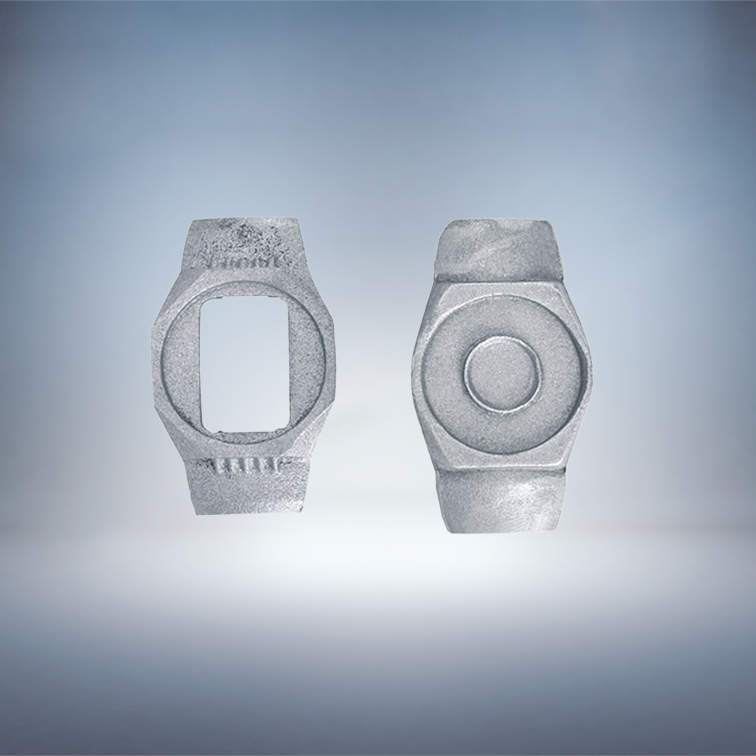

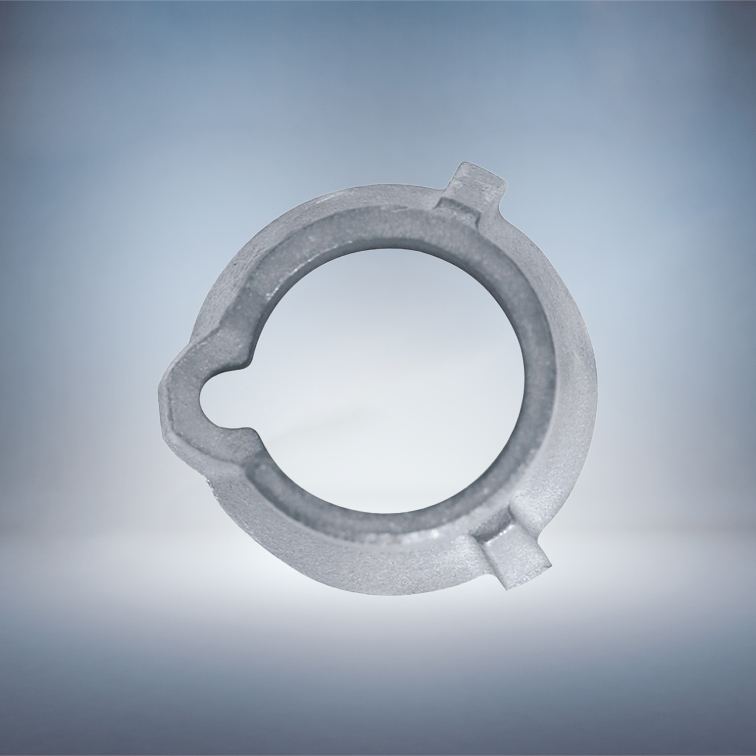

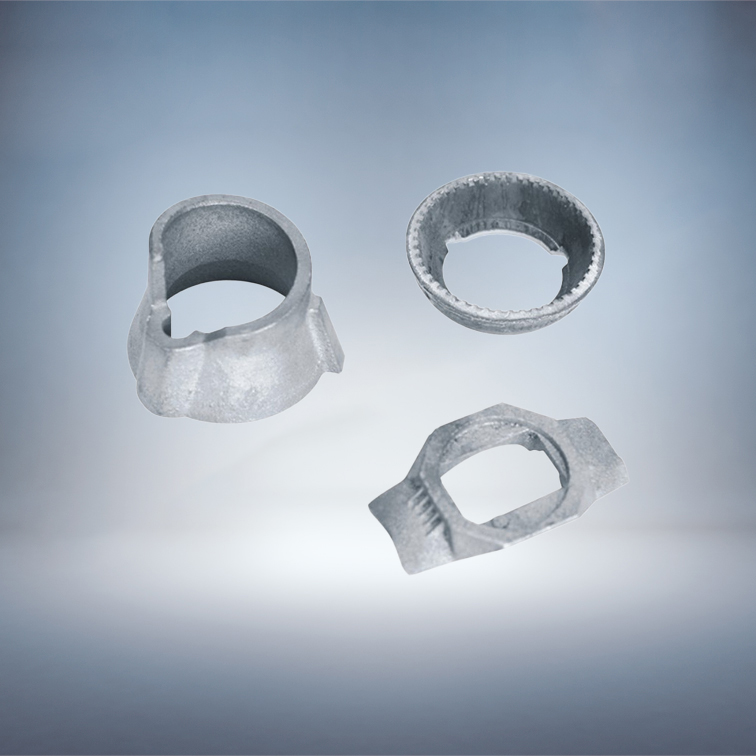

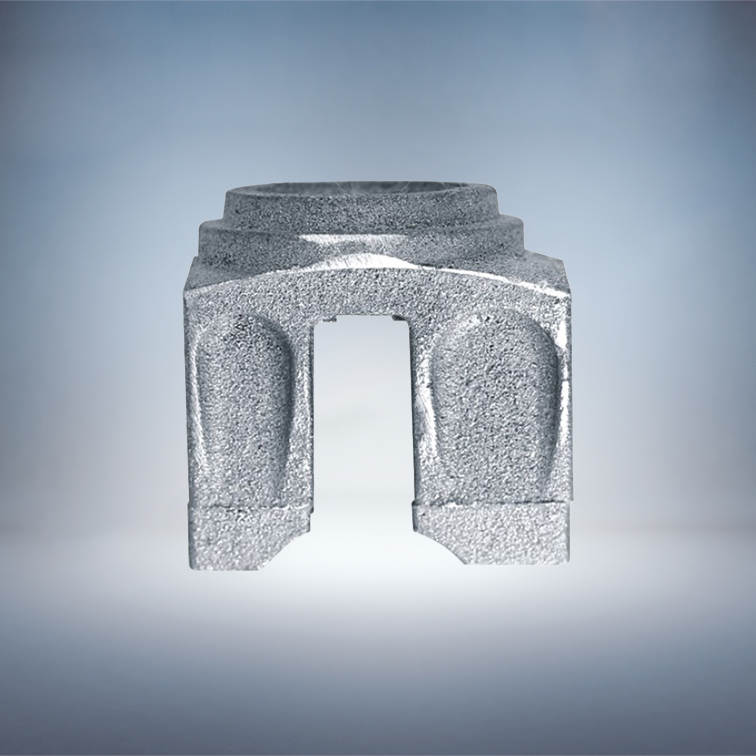

The Ringlock System is a complete modular scaffolding and shoring solution. Its core design philosophy centers on creating rigid, nodal connections between the rosette plates welded to the vertical standards and the wedge-shaped blades on the ends of ledgers and diagonals. This forms an efficient, safe, and reliable three-dimensional support structure. The system is suitable for a wide range of construction applications requiring temporary support, working platforms, and access solutions.

2. System Components & Features

-

Core Components:

-

Standards: Vertical load-bearing members with rosettes, forming the system’s backbone.

-

Ledgers: Horizontal members connecting standards, defining bay dimensions.

-

Diagonals: Provide lateral stability, essential for structural integrity.

-

Base Jacks & U-Heads: For leveling the system and supporting formwork.

-

-

Advanced Features:

-

High Nodal Strength: Connection strength approximates member strength, ensuring excellent structural integrity.

-

Precision Erection: Standardized modular design (e.g., 500mm spacing) guarantees a regular, predictable structure.

-

Material & Finish: Main components made from S355 high-strength steel, hot-dip galvanized for corrosion resistance.

-

Inherent Safety: Design eliminates hazards associated with loose fittings, ensuring high system reliability.

-

3. Key Technical Parameters

-

System Material: Primary components: S355JR High-Strength Steel.

-

Standard Specification: Common tube diameters: φ48.3mm or φ60.3mm, wall thickness ≥3.2mm.

-

Surface Treatment: Hot-Dip Galvanized (coating thickness ≥80μm).

-

Modular Spacing: Standard rosette spacing: 500mm or 1000mm.

4. Typical Applications

-

Building Construction: High-formwork support systems for super-high-rise and heavy-load structures.

-

Infrastructure: Support falsework for cast-in-situ bridge decks in highway and railway projects.

-

Industrial Construction: Construction platforms for power plants, petrochemical facilities.

-

Public Works: Construction of large-span structures like stadiums, theaters, and airport terminals.

-

Special Events: Stages, grandstands, and temporary structures for major events.