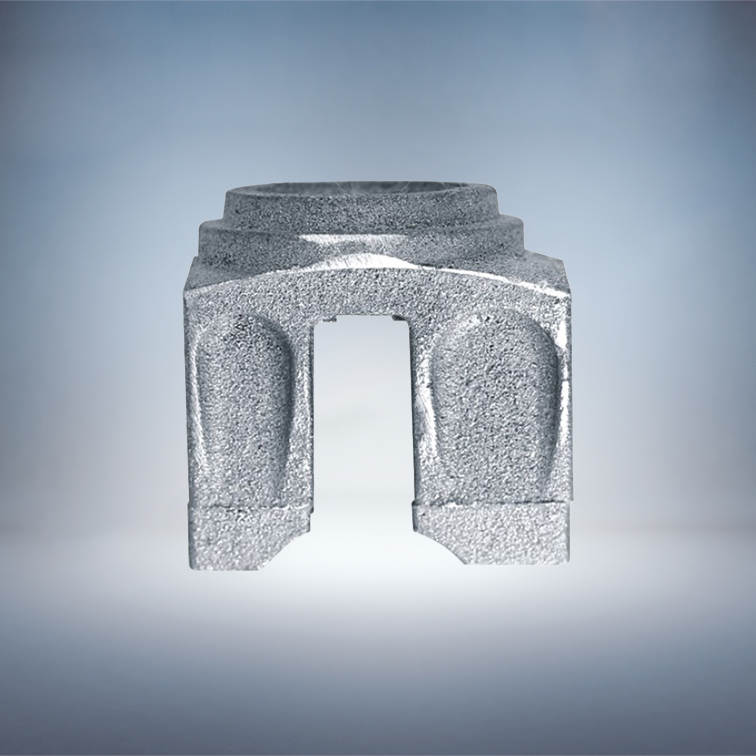

Facade Brace

The Facade Brace is a critical stability component engineered for standalone scaffolding systems. Its primary function is to provide reliable lateral support by tying the scaffold structure securely to the building facade or other stable points. It effectively resists wind loads and lateral forces generated during construction, preventing potential collapse. Designed for the challenges of elevated facade work, its rapid and secure connection method provides an essential layer of safety, making it an indispensable element for secure construction operations.

Description

1. Product Overview

The Facade Brace, also known as a wall tie or lateral brace, is a core safety component that ensures the stability of scaffolding systems (particularly standalone towers) under lateral loads such as wind and construction activities. It creates a stable triangulated system, transferring horizontal forces from the scaffold to the main building structure, which is critical for preventing collapse. The installation of facade braces in compliance with safety codes is a mandatory requirement for elevated scaffolding work.

2. Design & Features

-

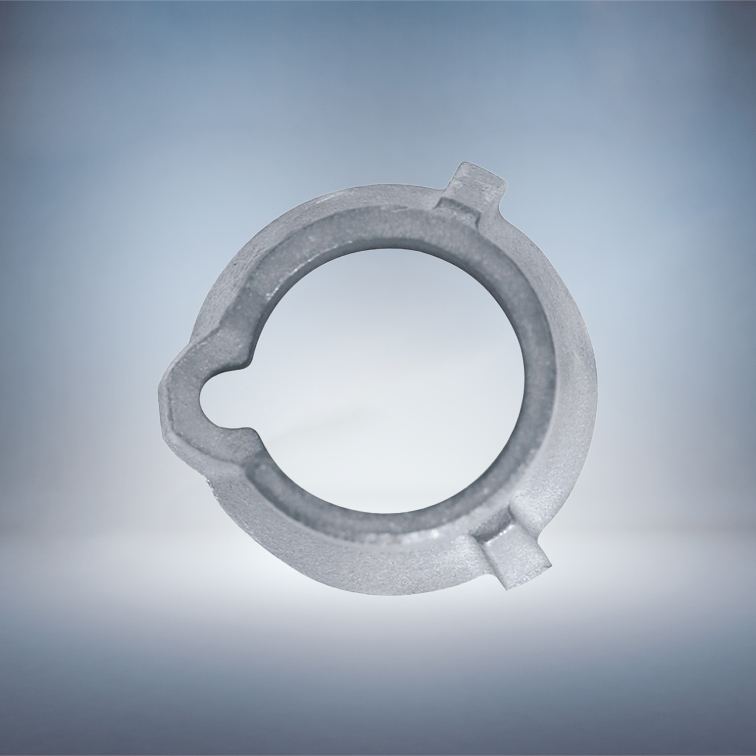

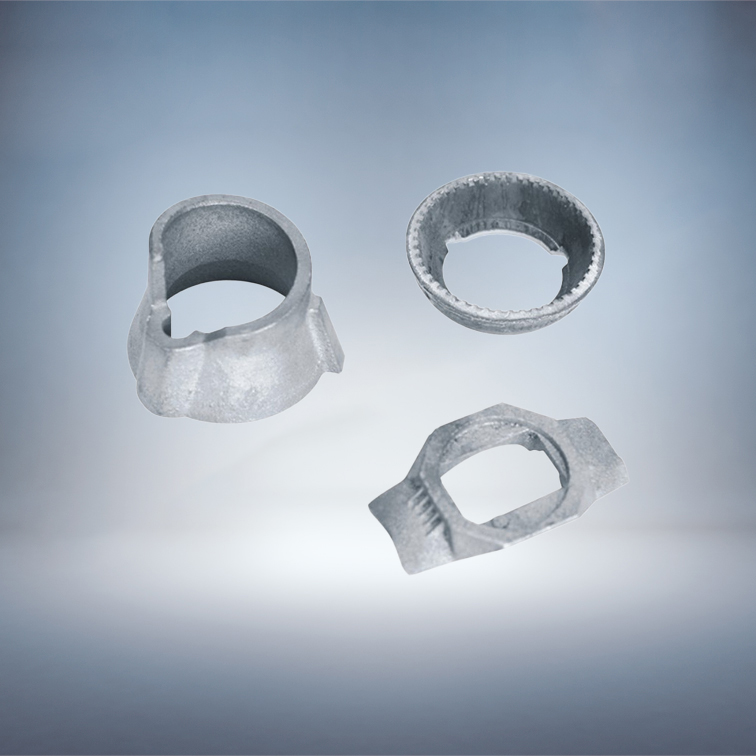

Body Structure: The main body is made from high-strength seamless or welded steel tube, ensuring excellent compression and bending resistance.

-

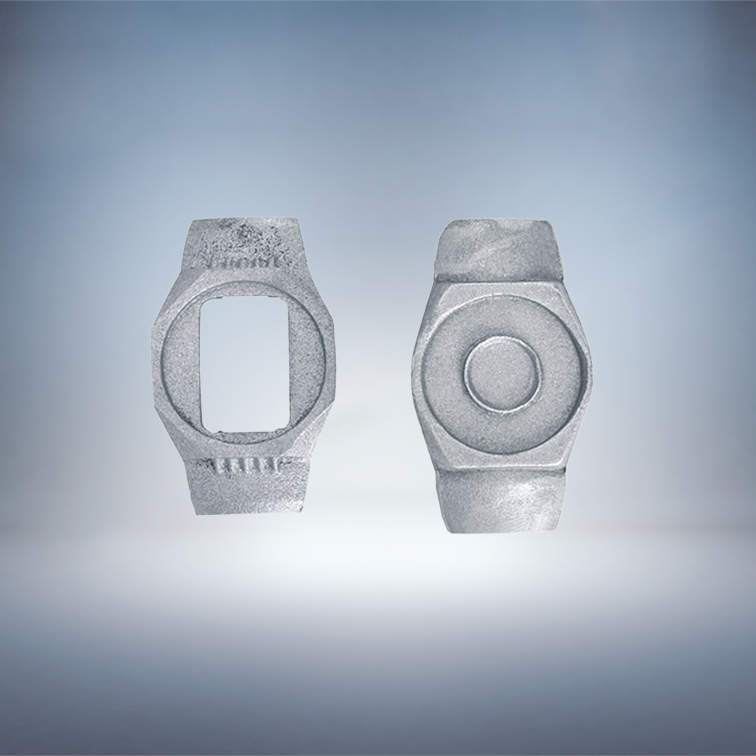

End Connectors:

-

Scaffold End: Typically features a swivel head or proprietary clamp for quick attachment to standards or ledgers.

-

Building End: Offers various options like adjustable wall pads, expansion anchor interfaces, or base plates for cast-in inserts to suit different wall structures.

-

-

Adjustability: Most designs incorporate a length-adjustment mechanism (e.g., threaded sleeve) for fine-tuning and applying pre-tension on-site.

-

Corrosion Protection: Full hot-dip galvanization provides comprehensive rust protection for extended service life.

3. Technical Parameters

-

Material: Steel Grade Q235B or Q355B (S235JR / S355JR)

-

Tube Diameter/Wall Thickness: φ48mm × 4.0mm

-

Working Length: Adjustable range (e.g., 1.5m – 3.5m) or available in fixed lengths

-

Surface Treatment: Hot-Dip Galvanized (coating thickness ≥55μm)

4. Application Guidance

-

Installation Spacing: Determined by scaffold design codes, height, and local wind load calculations, typically not exceeding specified distances (e.g., 6m) in both horizontal and vertical directions.

-

Installation Angle: The ideal angle of installation (to the horizontal) is recommended between 45° and 60° for optimal support efficiency.

-

Compatible Systems: Perfectly compatible with various standalone scaffolding systems, Ringlock, cup-lock systems, etc., for building facade construction, maintenance, and renovation.