Formwork tie rods

Formwork Tie Rods are critical load-bearing components in concrete pouring projects, designed to connect and tension opposing formwork panels against the immense lateral pressure of fresh concrete. Manufactured from high-strength alloy steel through precision machining and heat treatment, our tie rods offer exceptional tensile strength and durability. We provide a comprehensive range, including through-tie rods and disposable threaded tie rods, to deliver safe, efficient, and cost-effective solutions for formwork projects of all scales and complexities, ensuring precise concrete dimensions and smooth surface finishes.

Description

-

Product Name: Formwork Tie Rods

-

Key Features:

-

High Tensile Strength: Made from high-strength alloy steel (e.g., 45Mn, 40Cr), our rods withstand extreme concrete pressure, preventing formwork failure and ensuring worksite safety.

-

Comprehensive Specifications: Available in various diameters (M12, M16, M18, M20, M24, etc.) and lengths, with custom options to suit diverse needs, from walls/columns to large foundations and bridge piers.

-

Economic & Efficient (for Disposable Type): The innovative three-part tie rod system allows the outer parts and nuts to be reused while the inner section remains in the concrete. This saves material costs and leaves a small, neat hole in the finished wall.

-

Corrosion Resistance: Surface treatments like galvanization (hot-dip or electro) or Dacromet provide excellent rust resistance, ensuring longevity even in harsh environments.

-

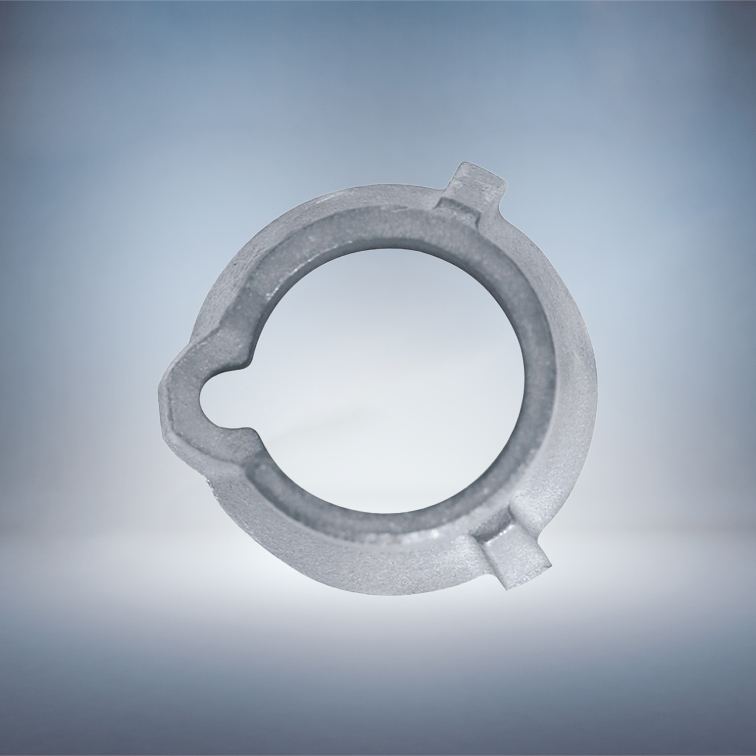

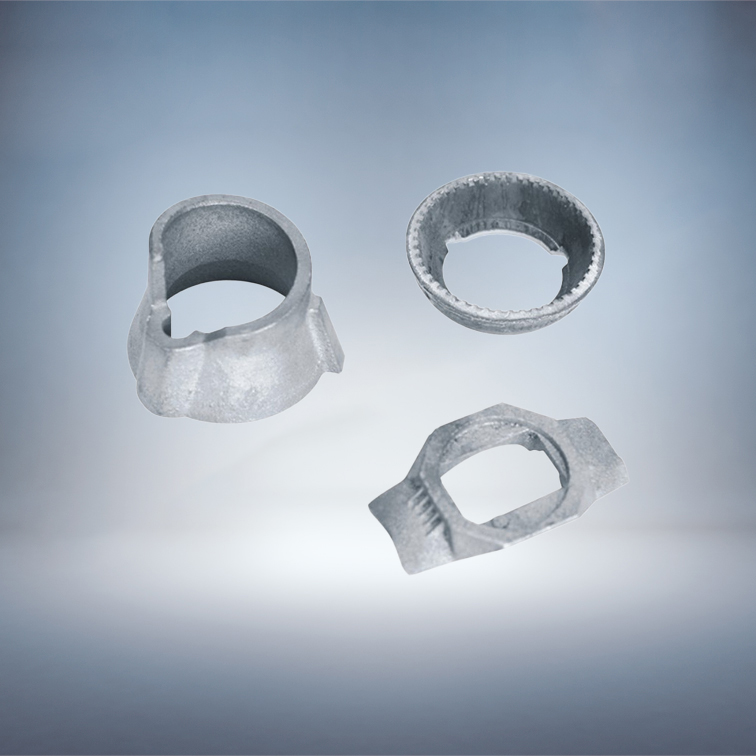

Easy Installation: Standardized threading works seamlessly with cone nuts and washers for quick assembly and disassembly, significantly boosting on-site productivity.

-

-

Product Types:

-

Through-Tie Rods: Feature continuous threading and are used with PVC sleeves. Suitable for thinner walls and are fully retrievable.

-

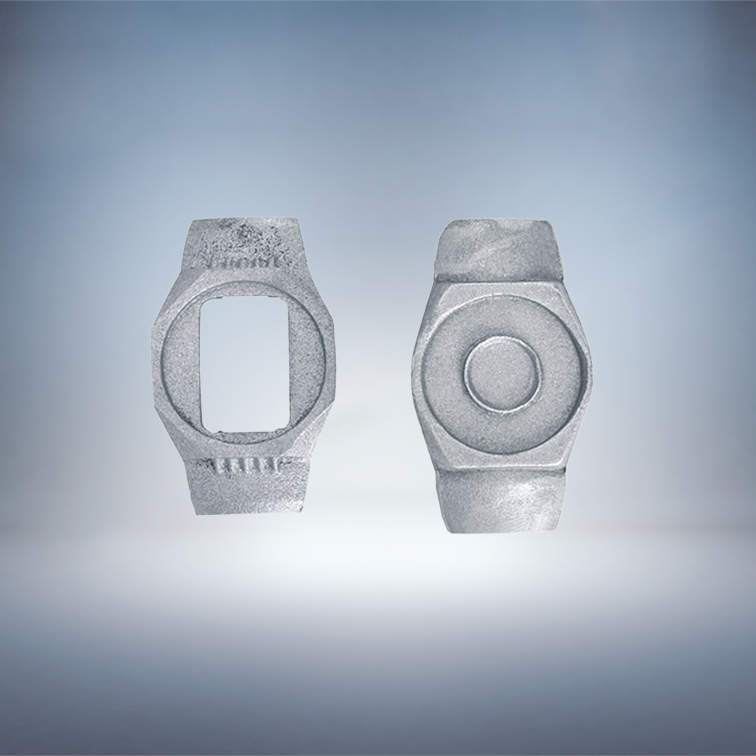

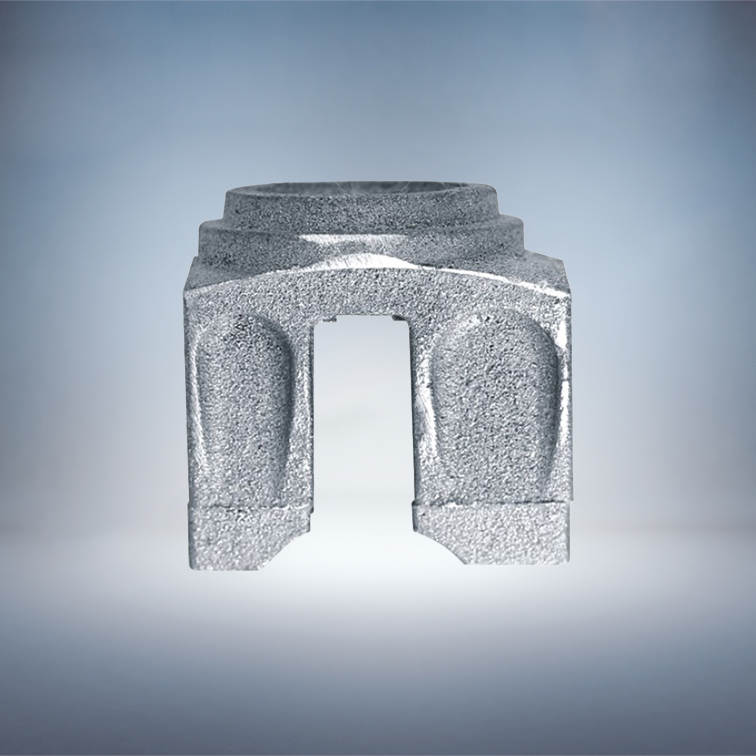

Disposable Threaded Tie Rods (3-Part System): Consist of an inner wedge and two outer rods. The outer components are reusable, making this a cost-effective and popular choice for modern formwork.

-

-

Applications:

-

Formwork for building walls, shear walls, and columns

-

Large-scale infrastructure: bridge piers, tunnel walls, dams

-

Industrial foundations and equipment bases

-

Any cast-in-situ concrete structure requiring resistance to lateral concrete pressure.

-

-

Technical Parameters:

-

Material: High-Strength Alloy Steel (45Mn/40Cr)

-

Strength Grade: Grade 8.8, 10.9, or higher

-

Diameter: M12, M16, M18, M20, M24, M30, etc.

-

Length: Customizable, ranging from centimeters to several meters

-

Surface Treatment: Hot-Dip Galvanized, Electro-Galvanized, Dacromet

-