Catwalk

Scaffold Plank: Building a Safe and Efficient Work Platform

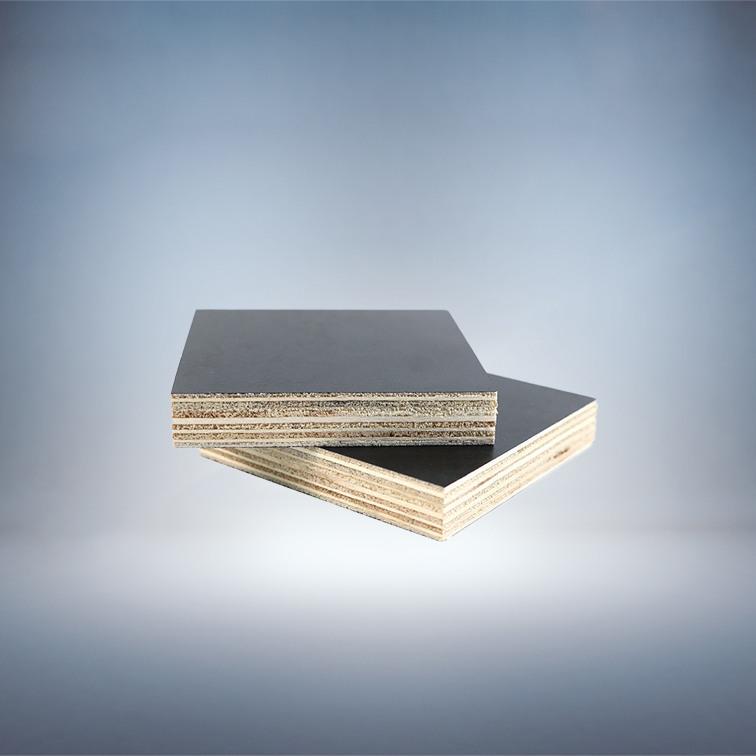

The Scaffold Plank is the critical working surface component of a standalone scaffolding system, directly supporting personnel, materials, and equipment at height. It provides a solid, stable, and safe platform for all operations. Our planks are engineered for superior load-bearing capacity and feature anti-slip properties. They integrate quickly with system bearers to create a level and secure platform, enhancing both productivity and safety for construction, bridge, and industrial projects.

Key Benefits:

Safe & Stable: High-strength construction and anti-slip design prevent shifting and slipping, ensuring safety at height.

Excellent Load Capacity: Engineered for optimal strength-to-weight ratio, reliably supporting designated live loads.

Durable & Long-Lasting: Steel or aluminum construction offers corrosion resistance and impact strength for a long service life.

Quick & Easy Setup: Standardized dimensions and simple placement allow for rapid platform assembly.

Description

1. Product Overview

The Scaffold Plank is the fundamental component used to create the working platform on scaffolding or standalone system bearers. Its primary function is to form a safe and continuous working surface that supports live construction loads (personnel, tools, materials). A high-quality plank is a critical defense against accidents like falls from height and falling objects. This product is designed to meet the high safety and efficiency demands of modern construction.

2. Design & Features

-

Material Types:

-

Steel Planks: Exceptional load capacity, high durability, cost-effective. Typically feature slip-resistant serrated patterns or grating.

-

Aluminum Planks: Lightweight for easy handling, excellent corrosion resistance, reduces worker fatigue and increases efficiency.

-

-

Anti-Slip Design:

-

Serrated Surface: Pressed ribs or holes on steel planks for increased friction.

-

Grating Design: Steel or aluminum grating offers superior slip resistance and allows for drainage, preventing buildup of water, ice, or mud.

-

-

End Hooks: Some models feature integrated end hooks or notches to prevent displacement or tipping on the bearers, enhancing safety.

-

Safe Edges: Smooth, rolled, or finished edges to prevent injuries and damage.

3. Technical Parameters

-

Material: Q235 Steel or 6061-T6 Aluminum Alloy

-

Standard Lengths: 1.0m, 1.5m, 2.0m, 2.5m, 3.0m (Custom available)

-

Standard Widths: 250mm, 300mm, 450mm

-

Thickness/Height: Steel: 1.2mm~1.5mm; Aluminum: ~50mm (Overall height)

-

Max Design Load per Plank: [Please insert your test data, e.g., UDL ≥ 2.0 kN/m² or Concentrated Load ≥ 1.5 kN]

-

Surface Treatment: Hot-Dip Galvanized, Painted (Steel); Anodized (Aluminum)

4. Application & Safety Compliance

-

Installation: Planks must be fully supported on at least two bearers, with sufficient overlap (typically min. 50mm) as per safety codes.

-

Platform Integrity: Platforms should be fully decked, with gaps between planks minimized to prevent tools/materials from falling.

-

Inspection: Planks must be inspected before use for significant deformation, cracks, or corrosion to ensure structural integrity.

-

Compatible Systems: Widely used with various standalone systems, Ringlock, cup-lock scaffolding, etc.